IoT revolution has already multiplied the opportunities in each and every sector. Unlike sectors like consumer appliances-smart home products, IoT in automotive and manufacturing sector differs a lot in its application. In case of this sector, IoT not only provides the insightful data to monitor the processes and make strategic decisions but also automates the complex processes improving the efficiency and ultimately the bottom line.

Large automotive and manufacturing plants have multiple processes, machines and their dozens of components at assembly lines. With an ability to monitor these activities and optimize process with continuous communication with various components, efficiency of the manufacturing processes is increased. Manufacturing companies across the globe are identifying the opportunities to optimize their operations using the IoT and facilitate data based automated decisions.

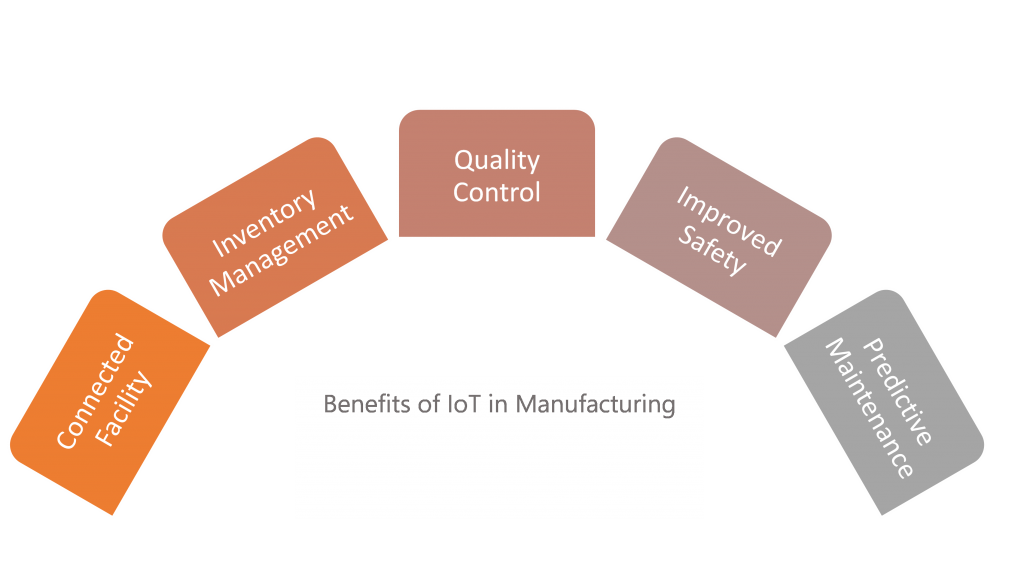

Some of the key manufacturing processes which are benefitted from application of IoT are

1. Connected Manufacturing Facility

With number of sensors exchanging the information about the ongoing processes and the machines itself, the whole facility will become integrated manufacturing unit and will enable the operations executives to manage the unit more efficiently, making the day to day activities effortless.

2. Efficient Inventory Management

Inventory Management is one of the crucial aspect in manufacturing as optimization of the inventory has major impact on the profitability of the company. Unavailability of the data is the major hurdle in making the well informed decisions, using the IoT systems that problem can be solved.

3. Predictive Maintenance

As opposed to the conventional maintenance activities where there were maintenance schedules for the preventive maintenance, IoT systems monitors the data of the manufacturing units in real time and will alert the responsible personnel when there is need for maintenance at the precise moment.

4. Quality Control

Entire manufacturing process from the raw material selection to the packaging of the finished product can be monitored with the help of the connected devices. The complete monitoring of the product life-cycle in real time provides the ability for the improvement in the product.

5. Improved Safety

Data collected from the IoT systems can help to analyse the factors responsible for the accidents and mishaps in various manufacturing units. The integrated system can communicate accordingly and the situation can be contained in time providing minimum downtime and higher safety to the employees.

IoT is surely powering the Industry 4.0 and though first movers are already realizing the benefits, there is still more time for late movers to make the most of this connected devices disruption.